Comprehensive Guide to PVC Extrusion Equipment and Pricing in Mexico

This guide details various PVC extrusion machines available in Mexico, covering types, benefits, and price ranges. It helps manufacturers choose suitable equipment for their production capacity, ensuring efficient, high-quality outputs. Understanding local options allows businesses to make informed investments and stay competitive in the plastic manufacturing sector.

Sponsored

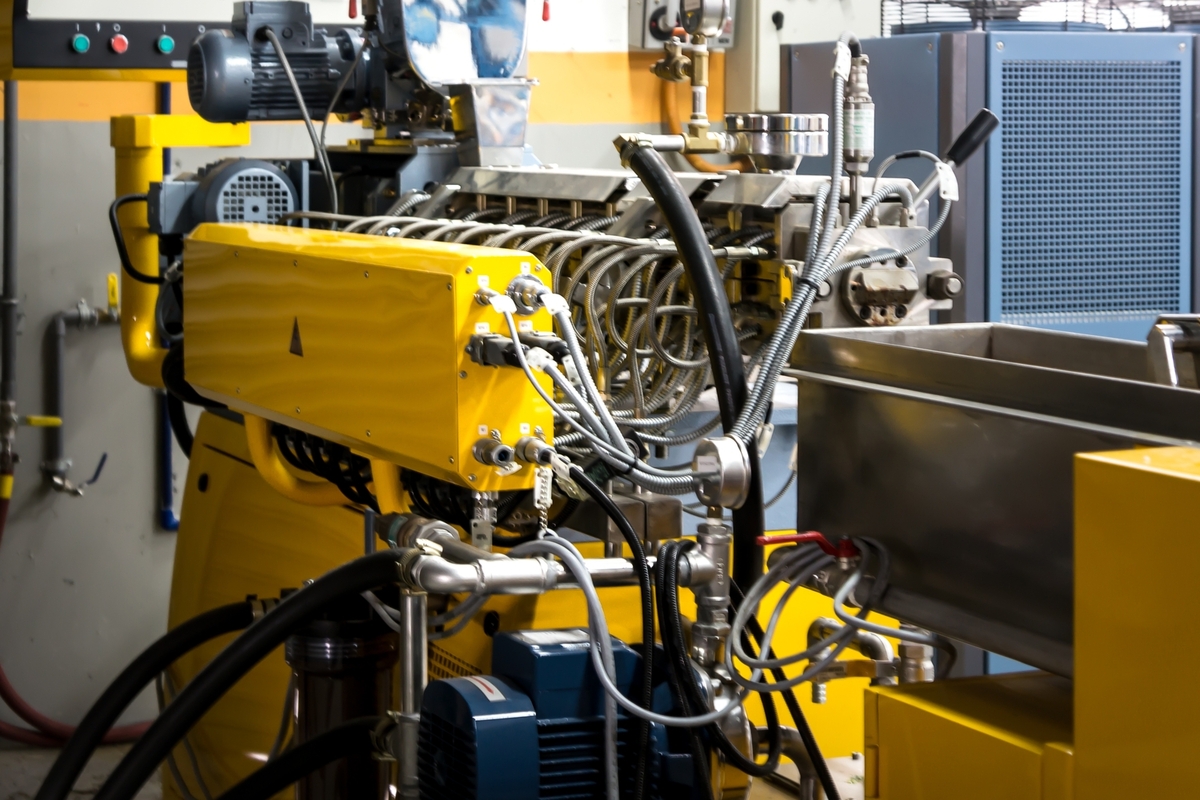

In Mexico's plastic industry, PVC extrusion machines are essential for manufacturing pipes, profiles, and sheets. The country offers a broad selection of equipment suited for diverse industrial needs. This article provides an overview of different types of PVC extruders available locally, along with their price ranges, to assist buyers in choosing the right machinery for their operations.

1. Single Screw Extruders

Overview:

These are the most widely used PVC extruders, featuring a single screw within a cylindrical barrel that directs molten PVC through a die to shape products.

Benefits:

Budget-friendly for fundamental PVC production needs.

Simple to operate and maintain.

Ideal for manufacturing pipes, sheets, and basic profiles.

Cost Range:

In Mexico, single screw extruders typically cost between $20,000 and $80,000, influenced by capacity, brand, and added features.

2. Twin Screw Extruders

Overview:

Featuring two intermeshing screws, these machines offer superior mixing and handling, making them perfect for complex PVC formulations with additives.

Benefits:

Excellent blending and homogeneity.

Higher efficiency and output than single screw models.

Suitable for sophisticated profiles and high-quality pipes.

Cost Range:

Prices range from $50,000 to $150,000 in Mexico, depending on screw design, brand, and capacity.

3. Conical Twin Screw Extruders

Overview:

These machines feature conical screws that aid in better feeding and melting, especially for large or complex PVC products.

Benefits:

Enhanced feeding and melting efficiency.

Optimal for large diameter pipes and intricate profiles.

Energy-efficient operation.

Cost Range:

Priced between $60,000 and $180,000 in Mexico, depending on specifications and manufacturer.

4. Parallel Twin Screw Extruders

Overview:

These machines have parallel screws rotating in the same direction, providing consistent material flow and excellent dispersion.

Benefits:

Reliable and efficient processing.

Ideal for producing premium PVC profiles and sheets.

High throughput with optimized energy use.

Cost Range:

Available in Mexico from $70,000 to $200,000, depending on features and capacity.

5. High-Speed PVC Extruders

Overview:

Engineered for high productivity, these extruders incorporate advanced technology to facilitate rapid production rates.

Benefits:

Massive output capacity.

Precise control over extrusion parameters.

Suitable for large-scale manufacturing operations.

Cost Range:

In Mexico, high-speed models are priced from $100,000 to $300,000, based on speed and tech features.

6. Compact PVC Extrusion Machinery

Overview:

Designed for smaller facilities, these machines save space while maintaining efficiency, perfect for medium-sized production.

Benefits:

Space-saving design.

Cost-effective for moderate production needs.

Easy to install and operate.

Cost Range:

These units are priced between $15,000 and $50,000 in Mexico, depending on features and capacity.

Choosing the right PVC extrusion equipment depends on production goals, material handling needs, and budget. Working with reputable Mexican suppliers ensures quality, reliable support, and maintenance. Understanding machine types and pricing helps companies make informed investment decisions, boosting productivity and industry competitiveness.

Note:

Prices mentioned are estimates and may vary based on supplier, customizations, and market conditions. Consult local manufacturers for accurate, current pricing. This article is for informational purposes only; always seek professional advice before purchasing equipment.