Key Tips for Selecting Custom Wire Form Manufacturers

Discover essential tips for selecting the best manufacturer for custom wire forms. Learn about prototyping capabilities, material quality, flexible design options, and reliable service to ensure you get high-quality, tailored wire products that meet your needs. Make informed decisions by choosing experienced, reputable suppliers that prioritize customer satisfaction and quality materials.

Sponsored

With numerous wire form producers available today, finding a reliable partner can be challenging. Here's a concise guide to help you select the ideal manufacturer for your custom wire form needs:

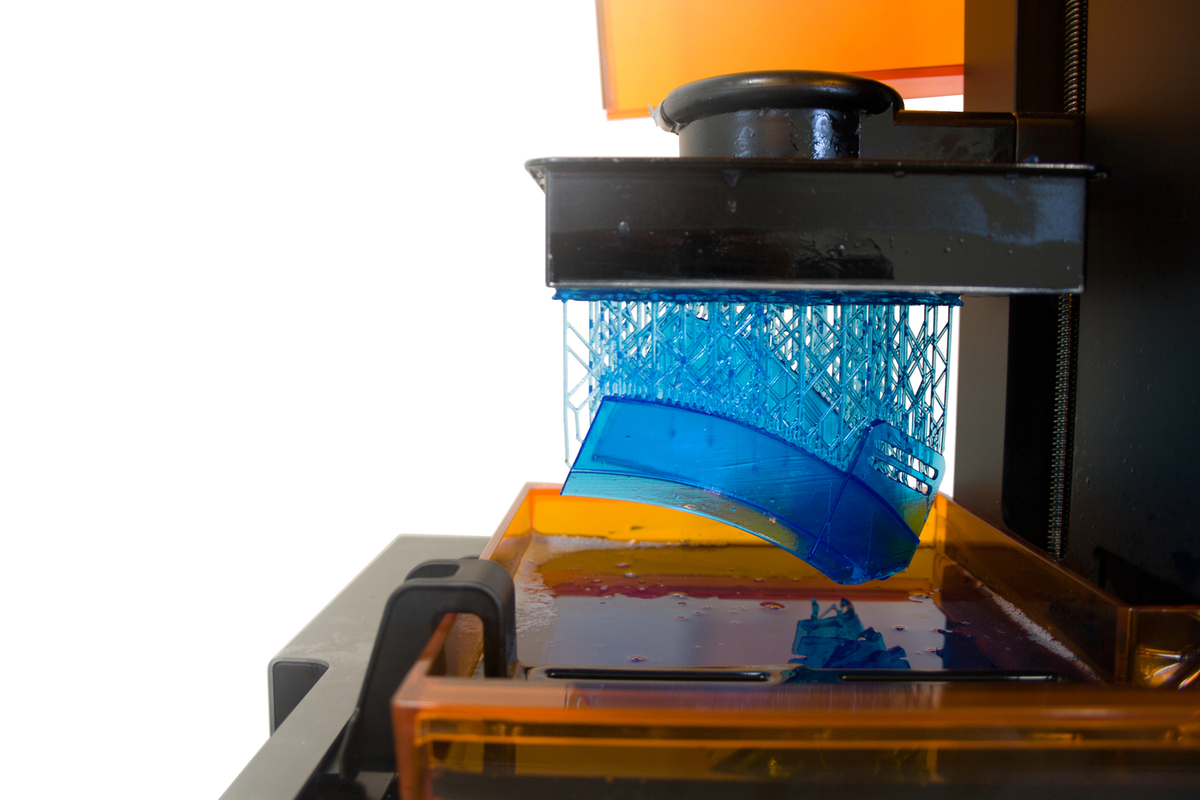

Look for companies offering prototype services

Advanced manufacturing techniques enable firms to produce prototypes, allowing you to verify fit and function early on. Prototyping also provides an opportunity to modify designs before mass production, saving costs associated with errors or redesigns.

If you are seeking top-tier suppliers for custom wire forms, prioritize those offering prototyping services.

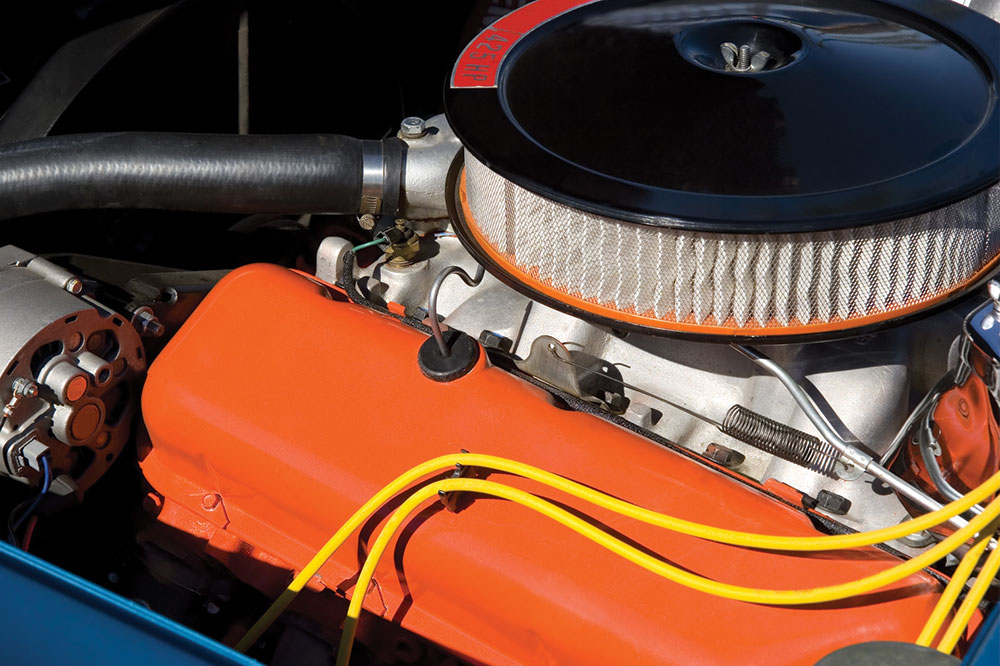

Ensure the use of premium materials

High-quality, durable materials are essential for producing robust wire forms. Avoid companies that cut corners on material quality; instead, opt for manufacturers known for using the best materials available to ensure longevity and strength.

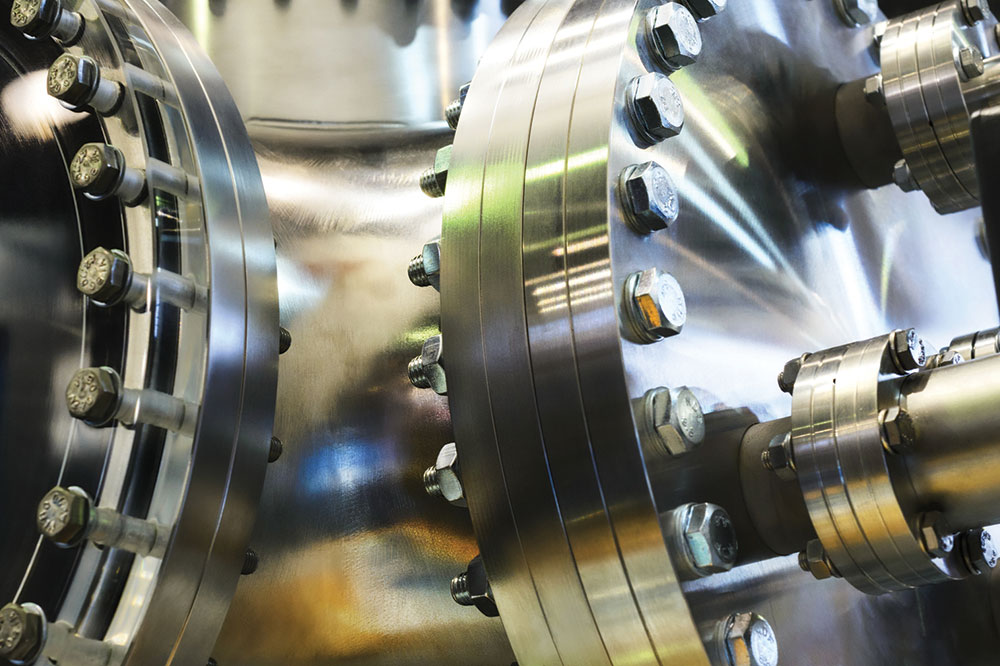

Choose manufacturers that offer limitless shape and size options

When purchasing custom wire forms, it's crucial that the manufacturer accommodates any design specifications. The ideal company can produce wire forms in any shape or size, fulfilling exact customer requirements without restrictions or compromises.

Additional factors include reliable delivery timelines and excellent customer service. Keep these considerations in mind to select a reputable provider for your custom wire forms.