Essential Tips for Buying Industrial Air Compressors in Mexico

Learn key tips for selecting the right air compressor in Mexico, from understanding your needs and technical specs to ensuring reliability and energy efficiency. This comprehensive guide helps you make an informed decision for industrial or residential applications, considering local regulations and cost factors for a smart investment.

Sponsored

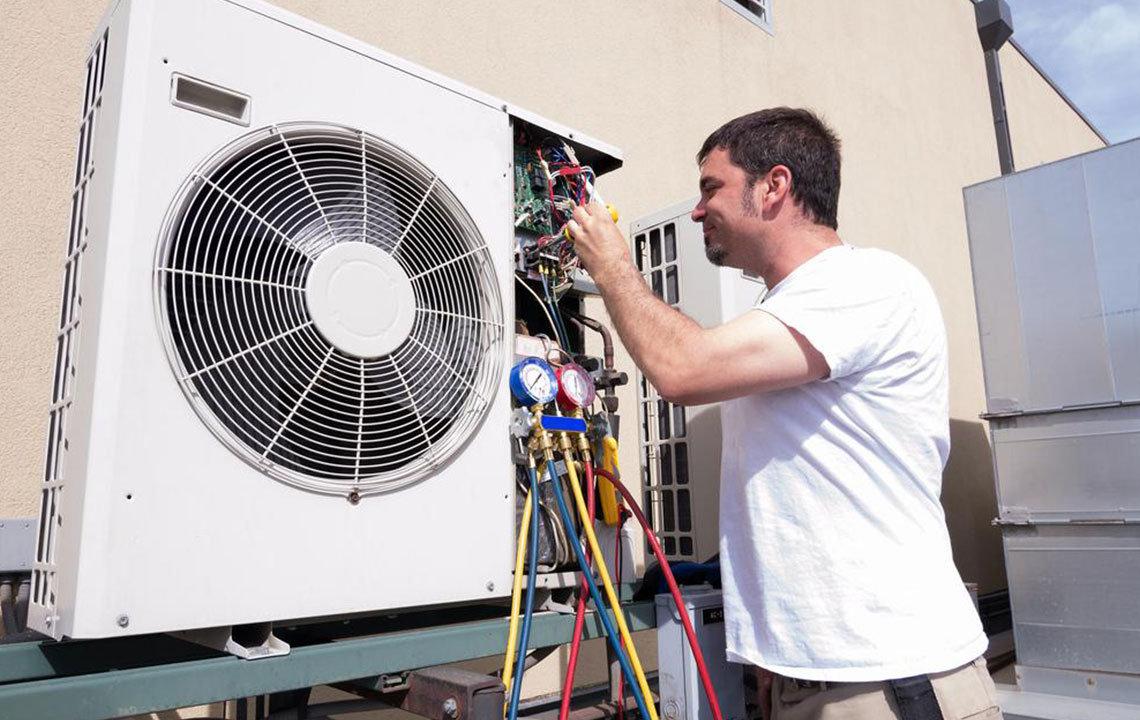

Selecting the right air compressor in Mexico requires careful consideration of various factors to ensure it fits your specific application. Air compressors are vital in industries like automotive, manufacturing, construction, and some residential uses. This guide highlights key points to help you make a well-informed purchase, focusing on your needs, technical features, and compliance requirements.

Assessing Your Needs

Start by understanding your particular demands:

– Application: Determine if the compressor is for industrial, commercial, or personal use. Heavy-duty models are suited for continuous industrial tasks, while lighter models fit home or small business needs.

– Power Source: Consider available power options in Mexico—electric, gasoline, or diesel—based on your facilities.

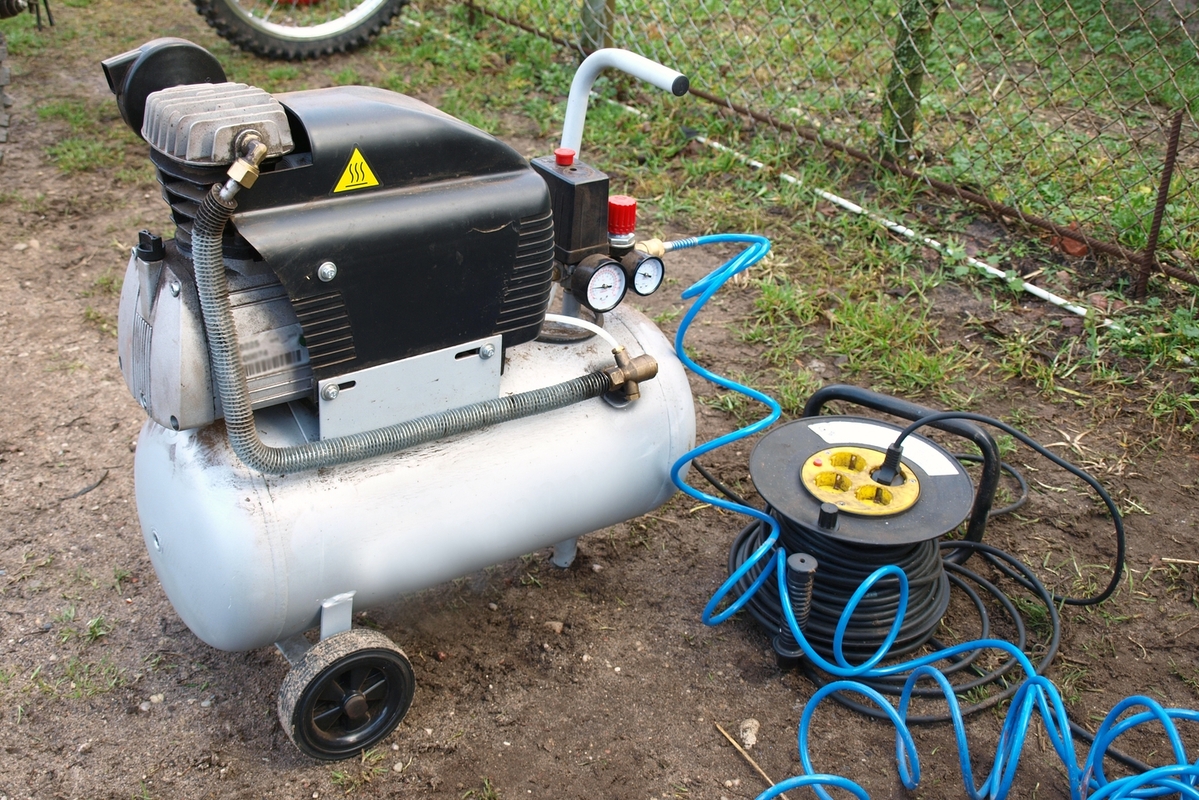

– Portability: Decide if you need a stationary unit for workshops or a portable model for on-the-go tasks.

Types of Compressors

Understanding different compressor types helps in choosing the best match:

– Reciprocating Compressors: Common and budget-friendly, suitable for both single and multi-stage operations requiring higher pressure.

– Rotary Screw Compressors: Known for efficiency and durability, ideal for continuous industrial use.

– Centrifugal Compressors: Designed for high-capacity needs in large-scale industries but costlier and more complex to operate.

Technical Features to Consider

Pay attention to specs like:

– CFM (Cubic Feet per Minute): Ensures adequate airflow for your tools; match or exceed your operational requirements.

– PSI (Pounds per Square Inch): The pressure level should align with your workload, with higher PSI for demanding tasks.

– Tank Capacity: Larger tanks allow extended use before needing to restart, beneficial in continuous operations.

Choosing Reliable and Long-lasting Equipment

Given the investment involved, focus on reliability:

– Brand Reputation: Opt for well-known brands with service networks in Mexico.

– Warranty: Check the warranty coverage; longer warranties often reflect higher confidence in product durability.

– Build Quality: Select models made from durable materials designed to withstand your working environment.

Maintenance and Parts Readiness

Maintenance ease and spare part availability are crucial:

– Maintenance Needs: Some units require regular oil changes and filter replacements—consider your readiness for upkeep.

– Spare Parts: Choose brands with readily available replacement parts and service centers in Mexico to minimize downtime.

Energy Efficiency Importance

Long-term costs can be reduced with energy-efficient models:

– Efficiency Ratings: Look for models with high efficiency to save on electricity costs.

– Variable Speed Drives (VSD): VSD models adapt motor speed to demand, lowering energy consumption significantly.

Budget and Cost Analysis

Consider both initial and operational expenses:

– Cost Over Time: Cheaper models may incur higher maintenance and energy costs later.

– Purchase Options: Leasing might be more suitable for short-term needs or limited budgets, compared to outright buying.

Regulatory and Compliance Checks

Ensure your compressor meets Mexican standards:

– Certifications: Confirm that the equipment complies with local safety and environmental regulations.

– Import Taxes: Be aware of potential import duties if sourcing internationally, to avoid unexpected costs.

Careful planning and understanding these factors will lead to selecting an air compressor that boosts your productivity, complies with local laws, and offers long-term value. Proper research ensures your investment remains efficient, reliable, and cost-effective over its lifespan.