Essential Materials for Effective Air Filtration

Discover the diverse materials integral to modern air filtration systems, vital for maintaining clean air in vehicles, buildings, and industrial applications. From activated charcoal to stainless steel mesh, learn how each component contributes to effective air purification and the importance of selecting the right material for specific needs.

Sponsored

Materials Used in Air Filtration Systems

Air filters play a crucial role in enhancing air quality by removing contaminants like dust, bacteria, and gaseous substances. They are vital in aircraft engines to ensure optimal air purity, and are also widely used in building ventilation systems. Advances in technology have significantly improved air filter designs and performance over recent years, driven by breakthroughs in aerodynamics and materials engineering.

The core filtering components vary based on specific application needs, making it important to select appropriate materials.

The composition of airborne particles differs across environments, necessitating tailored filtration solutions. Common filter materials include:

Activated Carbon – Utilized for odor control and removal of gaseous pollutants like ozone due to its charcoal content.

Polyurethane Foam – A dense foam material effective at trapping larger particles; historically popular in rally vehicle filters but now being replaced by advanced alternatives.

Electrostatic Materials – Generate static electricity to attract and eliminate airborne particles in ionizer-based filters.

Stainless Steel Mesh – Available in various sizes to provide durable, reusable filtration at different levels of precision.

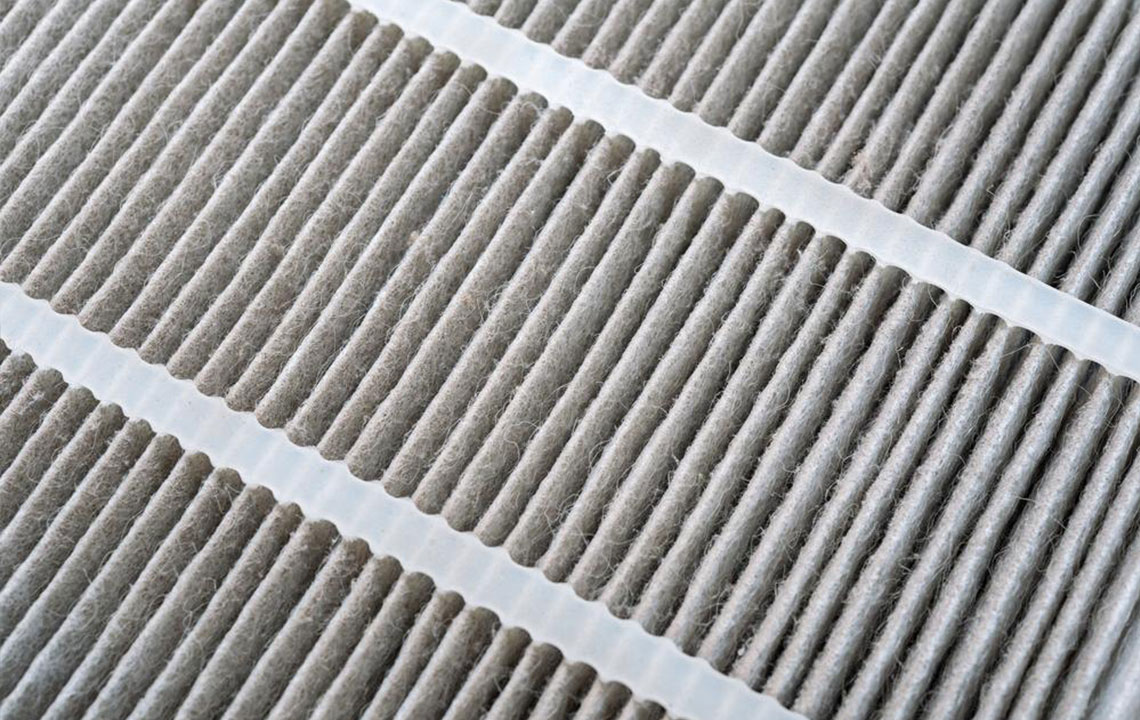

Paper – A cost-effective, widely-used filter medium, especially in automotive air filters, often in a pleated form for increased surface area.

Cotton – Emerging as a filter element, especially in air compressors, though its use remains limited.

Other Materials – Including polyester, oil baths, and water baths, often used in combination to optimize filtration efficiency. Selecting the best material depends on factors like cost, desired filtration level, and application specifics, ensuring optimal air quality performance.