Key Industrial Machinery in the Plastic Manufacturing Sector

This article explores essential industrial machinery in the plastics sector, highlighting their functions and significance. It covers equipment like laser cutters, capsule fillers, blow molding, and PVC extruders, emphasizing their role in improving efficiency and product quality in plastic manufacturing. Understanding these machines helps industry professionals optimize operations and achieve high standards in production.

Sponsored

The rapid expansion of the plastic industry hinges on advanced industrial equipment crucial for efficient production. These machines significantly boost productivity, reduce expenses, and improve product quality. Various types of equipment are employed throughout the plastic manufacturing process, each serving specific functions. In this overview, we explore the main categories of plastic machinery and their roles in industry.

Overview of Plastic Manufacturing Equipment

Plastic equipment encompasses multiple devices integral to processing and shaping plastics. The primary categories include injection molding machines, auxiliary processing units, secondary shaping machines, and compounding systems. Additionally, tools like CNC routers, film blowers, vacuum formers, rotational molders, granulators, and shredders support different production stages. These machines enable precise cutting, engraving, and trimming to produce high-quality plastic components.

Common Industrial Machines in Plastic Production

Below are essential machinery types utilized to achieve optimal results in plastic manufacturing:

1. Precision Laser Cutting Devices

Laser cutters are vital for detailed design work and exact shaping of plastics. Operating via CNC systems guided by CAD designs, these machines emit focused laser beams capable of cutting intricate patterns or etching surfaces. They are versatile, handling tasks like cutting sheet materials, engraving components, and even shaping small parts, making them indispensable in industrial and engineering applications.

2. Capsule Filling Equipment

Used predominantly in pharmaceuticals, capsule fillers automate the process of inserting active ingredients into capsules. These machines vary from manual to fully automatic, handling small batch fillings for personal use and large-scale production in industrial settings. The process involves filling capsules with medicaments, sealing them, and ejecting finished products for distribution.

3. Blow Molding Machines

Blow molding creates hollow plastic parts like containers and tubes by inflating heated plastic within molds. Available in extrusion, injection, and specialized forms, these machines feature components such as heads, extruders, and clamping systems. They are especially valued for producing packaging materials used in cosmetics and food industries, owing to their efficiency and ease of operation.

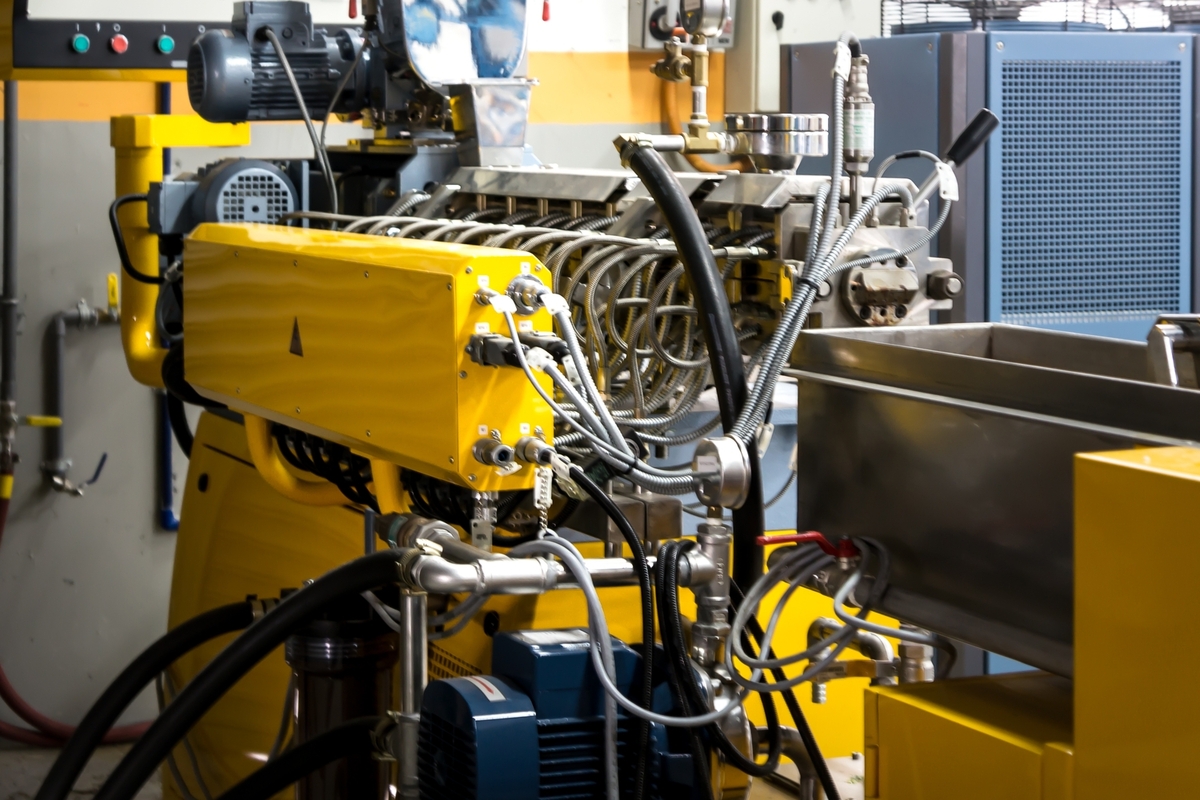

4. PVC Extrusion Machines

This equipment specializes in extruding PVC to form solid items such as sheets, profiles, and piping. With options for single or dual-cylinder setups, these machines are designed for delicate, precise shaping of plastic materials. Selecting suitable screws, barrels, and materials like high-carbon tool steels is crucial for optimal performance and durability.

As global demand for plastic products rises, industry-specific machinery continues to evolve, emphasizing maintenance and quality control. Well-maintained equipment enhances productivity, reduces waste, and ensures top-tier outcomes in plastic manufacturing processes.