Enhancing Manufacturing Efficiency in Mexico through Automation Technologies

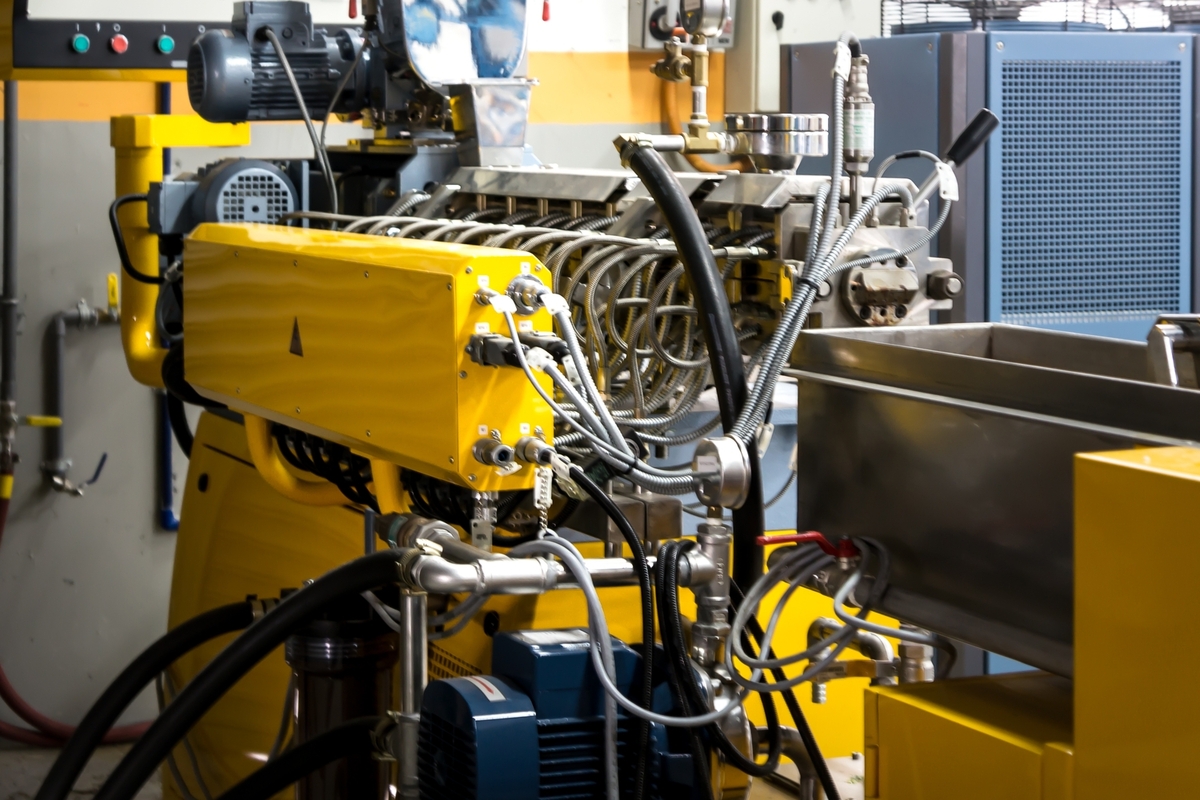

Automation tools are revolutionizing Mexican manufacturing by boosting efficiency, ensuring quality, reducing costs, and improving safety. From fixed to flexible automation, these technologies address key industry challenges, enabling factories to operate more effectively in a competitive global market. Embracing automation leads to higher productivity, safer workplaces, and better customer satisfaction, making it essential for modern manufacturing success.

Sponsored

Global manufacturing has undergone significant transformation, driven by the adoption of advanced automation solutions. Industries worldwide are integrating these technologies into their production lines to accelerate processes, cut costs, and reduce waste. This article discusses what automation tools are, the main types available, and how they address common manufacturing challenges.

What exactly are automation tools?

These are systems designed to control and streamline industrial tasks across various sectors, including quality assurance, data management, personnel oversight, and customer service.

Transitioning to automation reduces human errors, enhances process accuracy, and improves operational efficiency by delivering consistency and precision.

Categories of automation tools include:

Fixed automation: Designed for high-volume manufacturing of a specific product, these are ideal for industries like chemicals and automotive production, where machinery dictates process speed and sequence.

Programmable automation: Suitable for low-volume or batch processes, these systems can be reprogrammed to produce different products, such as programmable logic controllers (PLCs) that execute specific commands based on data inputs. However, reconfiguration involves downtime.

Flexible automation: In response to dynamic market demands, these adaptable systems can quickly modify production parameters, minimizing downtime. They connect remotely and integrate into larger networks, significantly boosting speed, accuracy, and scalability. Robotics and other flexible systems are vital in modern assembly lines and material handling, improving overall productivity.

Additional automation tools include:

SCADA: This system collects crucial operational data, enabling management to monitor and optimize processes in sectors like petrochemical, water treatment, and pipelines.

HMI: Human Machine Interfaces facilitate interaction between operators and machines, enhancing control and process management.

Neural networks: These models analyze data and support financial decisions, process optimization, and predictive analytics.

DCS: Distributed Control Systems oversee multiple industrial operations, commonly used in power generation, water management, and traffic regulation.

How automation addresses manufacturing challenges: With increased manufacturing activity in Mexico, automation plays a vital role in resolving issues like quality control and long lead times:

Boosted productivity: Flexible automation reduces changeover times and allows continuous 24/7 operations, maximizing output.

Consistent quality: Machines ensure higher precision, minimizing errors caused by fatigue or human oversight, and maintaining compliance with standards.

Lower operational costs: Despite initial investment, automation minimizes labor costs and waste, delivering long-term savings through increased efficiency.

Workplace safety improvements: Automation reduces human exposure to hazards and toxic substances, aligning with safety regulations such as Mexico's 1997 safety standards.

Data-driven insights: Real-time data collection supports continuous improvement and strategic planning.

Customer satisfaction: Consistent product quality fosters trust, enhancing brand reputation and customer loyalty.